The integrity of the turbine blades in an aircraft engine is essential for its safe operation. These blades are subject to a variety of stresses during the engine’s operation cycle, including rapid heating, sustained high temperature, and cooling. It is therefore vital to ensure that this repetitive cycle does not impact the structural integrity of any turbine blade since the failure of a single blade can affect other blades and cause the total engine failure.

The integrity of the turbine blades in an aircraft engine is essential for its safe operation. These blades are subject to a variety of stresses during the engine’s operation cycle, including rapid heating, sustained high temperature, and cooling. It is therefore vital to ensure that this repetitive cycle does not impact the structural integrity of any turbine blade since the failure of a single blade can affect other blades and cause the total engine failure.

A heat-controlled chamber is the standard method of testing designs for turbine blades. This procedure allows technicians to test different geometries and materials for optimal performance. Heat-controlled testing also provides the data needed for failure analysis and life expectancy of the proposed design.

Technicians can place the blade under a thermal load known as the ramp/soak period to simulate its operation in an engine. This procedure generally involves heating the test chamber at a specified rate to test various heat profiles. A constant temperature is then maintained for a designated period of time and allowed to cool. The blade may then be inspected for stress cracks, which could cause the blade to fail.

The primary challenge of testing turbine blades is they must be subjected to repetitive thermal cycling; otherwise the experimental requirement for a thorough simulation of the turbine blade damage factors under stress conditions, will not be satisfied.

The test chambers used in the aerospace industry are often customized for the specific size and configuration of the turbine blade being tested. This practice makes portability an essential feature of test equipment. Aerospace engineers and technicians also need to monitor the controller units remotely to adapt to the changing test conditions.

The PLATINUM™ Series Universal Digital Benchtop Controller from OMEGA Engineering is an ideal solution in quality lab environments. It combines enhanced ramp/soak programmability, complete portability, and remote monitoring via the Internet. The enhanced ramp/soak capability consists of up to 99 programs with 16 bidirectional ramps, including ramp/soak events and remote start. This unit also allows an aerospace technician to link individual ramp/soak profiles together to create a continuous cycling profile.

The controller's programmable dual three-color displays indicate both setpoint and real-time temperatures, easily read from anywhere in the test lab. Additional connections are directly accessible from the rear panel of the Universal Digital Benchtop Controller, including an internal 5A solid-state relay control output; power, fuse, and input connections; and an optional Ethernet port.

The OMEGA temperature controller is highly portable, giving it a flexibility that saves time and money. Technicians can easily move the unit to a different position in the test lab or to a different test chamber. It also comes with OMEGA Software, which is embedded firmware that can serve web pages over the Internet or an Ethernet LAN.

The OMEGA Software also allows technicians to monitor and control a test through a web browser and make modifications, such as changing setpoints or alarm points and turning the heater on and off during testing.

PLATINUM™ Series controllers make data collection, reporting, and analysis just as easy to accomplish outside of the office as they are in a quality lab. They also allow technicians to easily configure the optimal test parameters, ensuring the turbine blade is exposed to the required thermal cycling.

OMEGA’s thermocouple probes can accurately measure the test chamber’s temperature to ensure the integrity of the testing. Other OMEGA solutions can then record temperature versus time data, such as the Touch Screen Data Logger, USB Data Acquisition Module, and OMEGA’s Wireless Bluetooth® Transmitters.

CLOSE

CLOSE

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

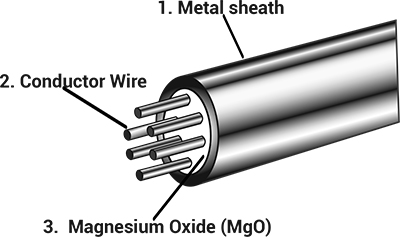

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why:

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why: