Thermistor

Introduction to Temperature Measurement with thermistors

A thermistor sensor is a

temperature-sensing element composed of sintered semiconductor material which exhibits a large change in resistance proportional to a small change in temperature. Thermistors usually have negative temperature coefficients which means the resistance of the thermistor decreases as the temperature increases.

Thermistors are made using a mixture of metals and metal oxide materials. Once mixed, the materials are formed and fired into the required shape. The thermistors can then be used “as-is” as disk-style thermistors. or further shaped and assembled with lead wires and coatings to form bead-style thermistors.

Choose the right thermistor

What is a Thermistor?

A thermistor, derived from the term THERMaIly sensitive reslSTORS, is a very accurate and cost- effective sensor for measuring temperature. Available in 2 types, NTC (negative temperature coefficient) and PTC (positive temperature coefficient), it is the NTC thermistor that is commonly used to measure temperature.

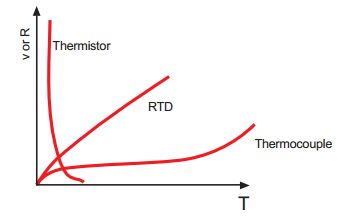

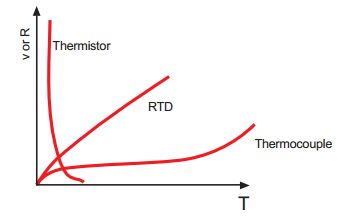

How Do They Compare to RTDs?

In contrast to RTDs that change resistance in a nearly linear way, NTC thermistors have a highly non-linear change in resistance and actually reduce their resistance with increases in temperature. The reasons that thermistors continue to be popular for measuring temperature is:

- Their higher resistance change per degree of temperature provides greater resolution

- High level of repeatability and stability

- Excellent Interchangeability

- A small size means fast response to temperature changes

Coatings typically include:

- Epoxy coatings for lower temperature use [typically -50 to 150°C (-58 to 316°F)]

- Glass coatings for higher temperature applications [typically -50 to 300°C (-58 to 572°F)

These coatings are used to mechanically protect the thermistor bead and wire connections while providing some protection from humidity and or corrosion. It is the epoxy bead-type thermistor that is used in Omega’s thermistor temperature sensor products.

Thermistors are typically supplied with very small diameter (#32AW or 0.008" diameter) solid copper or copper alloy wires. Many times, these wires are tinned for easy soldering.

Base Resistance

NTC thermistors drop in resistance with increased temperature. This is also true of the amount of resistance change per degree the thermistor will provide. Relatively low temperature applications (-55 to approx 70°C) generally use lower resistance thermistors (2252 to 10,000Ω). Higher temperature applications generally use the higher resistance thermistors (above 10,000Ω) to optimize the resistance change per degree at the required temperature. Thermistors are available in a variety of resistances and “curves”. Resistances are normally specified at 25°C (77°F).

How does a thermistor work?

Unlike RTDs and thermocouples, thermistors do not have standards

Unlike RTDs and thermocouples, thermistors do not have standards associated with their resistance vs. temperature characteristics or curves. Consequently, there are many different ones to choose from.

Each thermistor material provides a different resistance vs. temperature “curve”. Some materials provide better stability while others have higher resistances so they can be fabricated into larger or smaller thermistors.

Many manufactures list a Beta (B) constant between 2 temperatures (Example: [3 0/50 = 3890). This, along with the resistance at 25°C (77°F) can be used to identity a specific thermistor curve. See pages

this webpage for Omega’s thermistor curves.

Choose the right thermisor for your application

Thermistor Elements

Thermistor Elements

The thermistor element is the simplest form of thermistor. Because of their compact size, these elements are commonly used when space is very limited. OMEGA offers a wide variety of thermistor elements which vary not only in form factor but also in their resistance versus temperature characteristics. Since thermistors are non-linear, the instrument used to read the temperature must linearize the reading.

Thermistor Probes

Thermistor Probes

The standalone element is relatively fragile and can not be placed in a rugged environment. OMEGA offers thermistor probes which are thermistor elements embedded in metal tubes. There temperature probes are much more suitable for industrial environments than thermistor elements.

Learn more about Thermistors

What Thermistor is Best for My Application?

Whether you are replacing an existing thermistor, or selecting one for a new application, there are 3 key pieces of information needed to obtain the desired result. These are:

- Select the right base resistance for your new application, or correctly specify the base resistance of the thermistor needing to be replaced

- Specify a resistance vs. temperature relationship (“curve”), or for replacement applications, make sure you know the existing thermistor information

- Thermistor size or sensor package style

The most common thermistor resistances:

- 2252Ω

- 3000Ω

- 5000Ω

- 10,000Ω

- 30,000Ω

- 50,000Ω

- 1 MΩ (1,000,000)

Thermistor Accuracy

Thermistors are one of the most accurate types of temperature sensors. OMEGA thermistors have an accuracy of ±0.1°C or ±0.2°C depending on the particular temperature sensor model. However, these elements are fairly limited in their temperature range, working only over a nominal range of 0°C to 100°C .

Thermistor Stability

Finished thermistors elements are chemically stable and not significantly affected by aging.

Size or Sensor Package Style

Once the right resistance and “curve” are established, the user should consider how the thermistor will be used. When selecting the right size or packaging for the thermistor sensor, it helps to remember that like any other sensor, a thermistor only measures its own temperature.

Thermistor beads are generally not designed for direct immersion into a process. They are small devices that change temperature very quickly since the only thing between them and the environment is a thin coating of epoxy. At Omega, offer a comprehensive line of sensors that protect the thermistor while allowing it to be used in a wide variety of applications. Below are a sampling of some of these styles.

General Purpose

General purpose sensor designs are those that can be adapted to a wide variety of uses. Ranging from electronic equipment to structures, processes and design and reliability testing applications, these sensors are easy to install and monitor. The Omega

ON-950 is an example of this type of construction. A small SST housing with #8-32 threaded stud can be installed into any #8-32 threaded hole, taking up a very small amount of space.

Liquid Immersion Measurement

When exposed to liquids, thermistors need to be protected from corrosion as well as positioned into the fluid so it will come to the needed temperature. This is typically achieved using closed ended tubes and specially designed housings. Care must be taken to make sure that there is a good thermal path to the thermistor, and that thermal mass is as small as possible.

Surface Sensing

A simple but effective sensor design for monitoring surface temperature is the

ON-409 attachable su ace sensor. This design includes a thin, round metal stamping into which the thermistor is epoxied. The metal stamping can then be attached to a surface using an epoxy or other method to measure surface temperature.

Thermistor | Related Products

↓ View this page in another language or region ↓

CLOSE

CLOSE

Termistores

Termistores Thermistances

Thermistances Termistores

Termistores Termistores

Termistores Thermistors

Thermistors Termistorer

Termistorer Thermistances

Thermistances Thermistoren

Thermistoren Termistori

Termistori Thermistor

Thermistor Termistor

Termistor Thermistor

Thermistor Thermistors

Thermistors 热敏电阻

热敏电阻 Thermistors

Thermistors

サーミスター

サーミスター 써미스터

써미스터 Thermistors

Thermistors

Thermistors

Thermistors

Thermistors

Thermistors

Thermistors

Thermistors

Thermistors

Thermistors