In many industries it’s essential to know what a temperature product has been exposed to, and for how long. Whether sterilizing surgical instruments or medical devices, in an autoclave or heating food before canning, there should be evidence of temperature and time. Temperature monitoring helps facilities managers guard against legionella while environmental scientists gauge the health of rivers and streams by the temperature of the water. These and many similar processes can be monitored, and evidence obtained for verification, by using temperature data loggers.

In many industries it’s essential to know what a temperature product has been exposed to, and for how long. Whether sterilizing surgical instruments or medical devices, in an autoclave or heating food before canning, there should be evidence of temperature and time. Temperature monitoring helps facilities managers guard against legionella while environmental scientists gauge the health of rivers and streams by the temperature of the water. These and many similar processes can be monitored, and evidence obtained for verification, by using temperature data loggers. What is temperature data logger?

A temperature data logger is a form of data logger optimized or configured for temperature probes or sensors (and in the case of a temperature and humidity data logger, with humidity sensors too). A temperature logger is an electronic device capable of storing a number of measurements. Often battery powered, it accepts one or more sensor inputs, sampling and saving the data at a predetermined frequency. At the end of the acquisition period the logger is recovered and the data downloaded into a PC for analysis. Some data loggers even transmit the measurement results to a PC or other device, eliminating the need for field visits.

Types of temperature logger

At its heart every temperature logger comprises two elements: the temperature sensor or sensors and the recording system that samples the sensor at predetermined intervals and saves the measurement result. This sensor can be integrated directly with the recording system or be placed at some distance.

How does a temperature logger works?

Integrating a thermistor or thermocouple directly with a logger in a single package creates a compact, lightweight recording device. Its weakness is that it must be placed at a point where temperature is to be measured. This prevents internal sensor loggers being used in high temperature environments as the electronic elements in the device need to operate within a working temperature range. However, it makes them useful for logging temperatures experienced in-transit, as might be required when shipping artworks or perishable produce such as eggs.

With thermocouple input

With external probe attached

The problem of taking measurements in environments too hot or cold is addressed by using a temperature data logger with a probe attached (OMEGA’s OM-CP-HITEMP140-FP is an example of a high temperature logger with a flexible probe). This allows the recorder to remain in one environment while the sensor is placed somewhere different. For example, it would allow logging the temperature in an oven where the logger itself might not survive.

General purpose and temperature loggers are available with as many as 32 inputs (if single-ended—16 if differential). They will work with thermistors and thermocouples as well as 2-, 3- or 4-wire RTD temperature sensors.

Data retrieval

Many data loggers with an internal sensor are designed like a USB drive and will plug into a USB port on a computer for data download. Others loggers use the USB interface but require a separate cable. Another option is to use a Bluetooth® interface from the logger to a PC or even a mobile device. Some loggers can be used on an Ethernet network to send data back to a central PC while others use wireless to send measurements. Both approaches eliminate the requirement to travel out to a logger in the field to recover the data.

Applications

Temperature measurement is important in applications ranging from monitoring the health of rivers and streams to verifying that sterilization procedures have been performed correctly. In some cases, measurements are needed over extended periods as a way of determining long term trends. In others the concern is to know the maximum or minimum temperature attained and the duration of exposure.

Humidity and temperature logging

In facility management, especially where precision measurement or temperature-sensitive processing is carried out, a record of temperature and humidity variation can be useful in identifying inefficiencies. The same holds true in plant and animal propagation. A particular concern for a facilities manager is the protection against legionella which can cause a potentially fatal form of pneumonia. In applications like these a combination of temperature and humidity data loggers provide a time-stamped record of the experienced conditions over an extended period.

Another situation where a time-stamped record is useful is the transportation of artworks. Here just the knowledge that conditions are being monitoring may provide an added incentive for careful treatment!

Another situation where a time-stamped record is useful is the transportation of artworks. Here just the knowledge that conditions are being monitoring may provide an added incentive for careful treatment!

High temperature logging

While there is no rigid definition of “high temperature” a recording device intended for temperatures in excess of 80°C (176°F) is usually considered a high temperature data logger. High temperature environments include autoclaves, pasteurization, and food and material processing. Food canning is one example. Here manufacturers must have evidence that product has reached the minimum temperature needed to destroy organisms like botulism. Loggers for such environments often incorporate a probe to allow the sensitive electronics to be kept out of hot conditions.

Water temperature logging

Aquariums benefit from monitoring water temperature to ensure a continued healthy environment for their fish, many of which can only survive within a narrow range. In similar vein, scientists use the temperature of rivers and streams as an indicator of the health of those ecosystems. Both are good applications for a water temperature data logger but they place differing demands on the equipment.

In an aquarium, the logger will be readily accessible so there is less requirement for extensive memory capacity and the data may be recovered either through direct PC connection or by Bluetooth. Conversely, gathering useful data about river temperatures may mean leaving the logger in-place for many months. Under such circumstances memory capacity, battery life and possibly wireless capabilities all take on a greater importance.

In an aquarium, the logger will be readily accessible so there is less requirement for extensive memory capacity and the data may be recovered either through direct PC connection or by Bluetooth. Conversely, gathering useful data about river temperatures may mean leaving the logger in-place for many months. Under such circumstances memory capacity, battery life and possibly wireless capabilities all take on a greater importance.

Cold chain

Many foods and some pharmaceuticals must be shipped under carefully controlled conditions to avoid spoilage. Including a compact temperature data logger placed in with the transported materials to provide a record of the conditions experienced. This helps to ensure the integrity of the products and provides evidence should any claim of mishandling arise.

Next steps

With so many temperature data loggers available, it can be difficult to select the right one. Only by understanding the reasons for temperature logging can the most important properties be identified and the range of possible equipment narrowed down. OMEGA Engineering has an online Data Logger Product Finder tool to assist with the process, but should questions remain contact OMEGA's technical professionals for suggestions on the right equipment for your unique application.

CLOSE

CLOSE

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

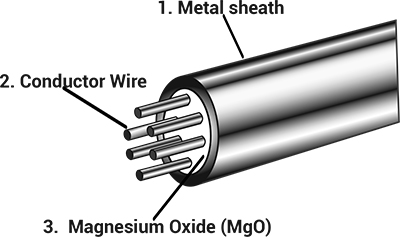

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why:

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why: