Wireless temperature monitoring uses the same Wi-Fi technology as home or business networks. It is very fast. Wi-Fi signals can be made to cover large areas through the use of repeaters and boosters, so it is an ideal solution for large installations. Without boosters, wireless has a range of about 1,000 meters if there is no interference.

Wireless temperature monitoring uses the same Wi-Fi technology as home or business networks. It is very fast. Wi-Fi signals can be made to cover large areas through the use of repeaters and boosters, so it is an ideal solution for large installations. Without boosters, wireless has a range of about 1,000 meters if there is no interference. Wi-Fi signals are easily intercepted, so it’s important to have appropriate safeguards such as firewalls in place. Wireless monitoring is less expensive to set-up than wired solutions in existing installations, since there is little or no cabling required. Wi-Fi can connect a diverse variety of devices from PCs on desktops to PLCs on equipment, along with mobile devices and VoIP phone systems.

The fastest wireless networks run on a standard called 802.11n, which has a maximum transmission rate of 600 Megabits per second with multiple antennas and no competition from other devices. Wireless runs on 2.4 GHz and 5 GHz bands.

IEEE 802.15.4 standard at 2.4 GHz is another wireless protocol that is ideal for conditions where battery life considerations are important, such as remote locations or dangerous environments. IEEE 802.15.4 is good for low to moderate volumes for data acquisition and logging and provides the added advantage of simple connectivity. The 2.4 GHz band is open for private use throughout the world, making it popular for industrial solutions. This standard allows for both point-to-point and point-to-multi-point configurations, so it works well in both simple and complex networks and remote temperature monitoring solutions.

Zigbee builds off the IEEE 802.15.4 protocol and adds additional capabilities such as more robust routing and networking. Zigbee is ideal for situations where data must be relayed from point-to-point but some radios are located outside the typical wireless range. The Zigbee mesh networking forwards data between nodes until it reaches the desired node.

Pros of Wireless Monitoring

- Fast transmission speeds

- Inexpensive installation in existing locations

- Flexible connections

- Handshaking ensures accurate data transmission even if data must be resent

- Ideal for monitoring remote locations like storage tank levels

- Multiple protocols enable a wide range of solutions to allow usage in widespread or congested environments

Cons of Wireless Monitoring

- Susceptible to interference

- Requires strong security

CLOSE

CLOSE

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

Omega's relationship with Rutgers sprouted with their goals in substituting manual processes with an IoT solution for hands-off data collection capabilities.

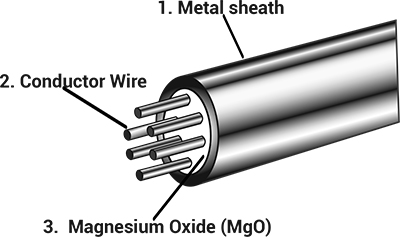

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why:

MI cables are used in high temperature or high pressure harsh environments for a good reason, here's why: