How does a positive displacement flow meter work?

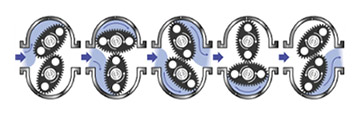

Positive Displacement flow meters are the only flow measuring technology to directly measure the volume of fluid that passes though the flow meter. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber. This can be compared to repeatedly filling a beaker with fluid and pouring the contents downstream while counting the number of times the beaker is filled.

Positive Displacement flow meters are the only flow measuring technology to directly measure the volume of fluid that passes though the flow meter. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber. This can be compared to repeatedly filling a beaker with fluid and pouring the contents downstream while counting the number of times the beaker is filled. Rotor rotational velocity is directly proportional to flow rate, since the flow of fluid is causing the rotation.

In electronic flow meters the rotating components contain magnets that activate various sensor options located outside the fluid chamber. Mechanical positive displacement flow sensors rely on the rotation to drive either a magnetic coupling or a direct gear train connected to the mechanical counter.

PD flow meters do not require a power supply for their operation and do not require straight upstream and downstream pipe runs for their installation. Positive displacement flow meters are available in sizes from in to 12 in and can operate with turndowns as high as 100:1, although ranges of 15:1 or lower are much more common. Slippage between the flow meter components is reduced and metering accuracy is therefore increased as the viscosity of the process fluid increases.

The process fluid must be clean. Particles greater than 100 microns in size must be removed by filtering. Positive displacement meters operate with small clearances between their precision-machined parts; wear rapidly destroys their accuracy. For this reason, PD meters are generally not recommended for measuring slurries or abrasive fluids. In clean fluid services, however, their precision and wide rangeability make them ideal for custody transfer and batch charging. They are most widely used as household water meters. Millions of such units are produced annually. In industrial and petrochemical applications, Positive displacement flow sensors are commonly used for batch charging of both liquids and gases.

Although slippage through the positive displacement flow meter decreases (that is, accuracy increases) as fluid viscosity increases, pressure drop through the meter also rises. Consequently, the maximum (and minimum) flow capacity of the flow meter is decreased as viscosity increases. The higher the viscosity, the less slippage and the lower the measurable flow rate becomes. As viscosity decreases, the low flow

Are DP meters accurate?

Another benefit is the flow meters ability to process a huge range of viscosities and it is not uncommon to experience higher levels of accuracy while processing high viscosity fluids, simply due to the reduction of by-pass. When considering and comparing flow meter accuracy, it is important to be aware of both ‘linearity’ i.e. the positive displacement flow meters ability to accurately measure over the complete turndown ratio, and ‘repeatability’, the ability to remain accurate over a number to cycles. This is another area where positive displacement flow meters excel, repeatability of 0.02% and 0.5% linearity are standard.

Reliability

If the correct flowmeter has been selected for an application it can be expected to perform without error for many years. Frequently PD flow meters are sent in for servicing and recalibration that have been in the field for 10 sometimes 20 years continuous use. This reliability is largely due to the fact that this same proven technology has been in use for over 60 years, allowing the major advances to be focused within the fields of tribology and achieving the required precision at a reasonable cost.

Low Maintenance

Benefits Summary

- High level of accuracy (0.5% as standard) higher level of accuracy available upon request

- Ability to process a large range of fluid viscosities <1 cP – >500000 cP

- Low maintenance

- High pressure capabilities

- Electronic and mechanical flow meter versions available

- Spare parts availability

Limitations and Considerations

While positive displacement flow sensors are very robust, there are limitations to their usage. Firstly they should not be used for fluids that contain large particles, unless these can be filtered out prior to the fluid entering the measuring chamber. They are also not suitable for applications where large pockets of air are present within the fluid; however air eliminators are available for these applications. Another factor that requires consideration is the pressure drop caused by the PD meter; although these are minimal they should also be allowed for in system calculations. As mentioned above when processing fluids with poor lubricating properties, it is recommended that advice is sought from your distributor; various material options are available for these applications.

CLOSE

CLOSE

Ultrapure or high purity water has been purified to tight specifications to...

Ultrapure or high purity water has been purified to tight specifications to...

Ultrasonic flow meters are non-intrusive devices that use acoustic vibrations to measure the flow rate of liquid...

Ultrasonic flow meters are non-intrusive devices that use acoustic vibrations to measure the flow rate of liquid...

Indoor air quality is the responsibility of building owners, managers and employers.

Indoor air quality is the responsibility of building owners, managers and employers.